UCT ELECTRODES ENGINEERING EQUIPMENTS (U.C.T.EEE) Specialty Products ensures 100% of all graphite electrodes and nipples meet industry quality standards; are the correct grade, specification and size for the application; have passed final inspection and then are carefully packaged for delivery. This quality product assurance combined with accurate and timely shipments provides a trouble – free start to finish electrode order process. Product quality assurance consists of an accurate visual test along with many automated QA tests before the final inspection.

UCT ELECTRODES ENGINEERING EQUIPMENTS (U.C.T.EEE) Specialty Products ensures 100% of all graphite electrodes and nipples meet industry quality standards; are the correct grade, specification and size for the application; have passed final inspection and then are carefully packaged for delivery. This quality product assurance combined with accurate and timely shipments provides a trouble – free start to finish electrode order process. Product quality assurance consists of an accurate visual test along with many automated QA tests before the final inspection.

- Home

- Products

Graphite Electrodes

Carbon Electrodes

Graphite Male – Female Rods

Special Graphite Blocks-ISO Pressure

Special Graphite Blocks-Vibration

Special Graphite Blocks-Mound Pressure

Special Graphite Rods-Vibration and Extrusion

Graphite Anode-Sheet and Rods

Graphite Tubes

Graphite Rotor

Graphite Crucible

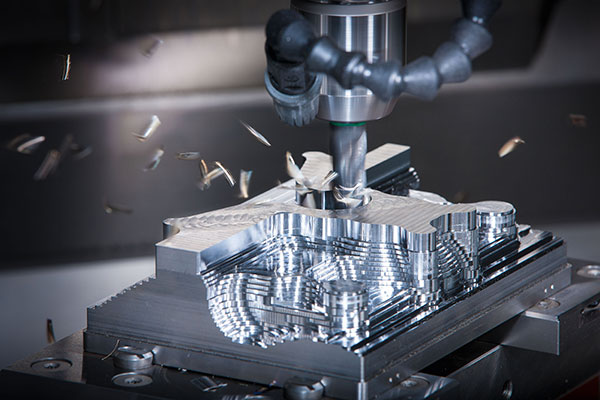

Graphite Machining

- Graphite Matrix for Boron Nitride Crucible

- Graphite Mesh (Hold Plate)

- Graphite Sintering Mould for Diamond Tools

- Graphite Seal Ring

- Graphite Joint Part for Gearing for Vacuum…

- Parts for Graphite Gear Box in Vacuum…

- Graphite Heater for Vacuum Electric Furnace

- Graphite Mould for Extracting and Purifying…

- Graphite Spray Nozzle for Diamond Drill…

- Graphite Sintering Plate

- Graphite Diversion Plate for Fuel Cell

- Graphite Crucible for Smelting Gold

- Graphite Funnel for Flowing Smelted Liquid…

Graphite Scraps and Powder

Billet

Bloom

Slab

Graphite CNC Machining

- About Us

- Services

- News

- Contact